Conveyor belts are the backbone of food and beverage manufacturing—moving product through each step with speed and precision. But when these belts begin to wear or delaminate, especially along the

Out of sight shouldn’t mean out of mind, especially when it comes to outdoor storage and trash collection areas at your food or beverage facility. That “temporary” collection zone full

They’re invisible. They’re resilient. And they could be the reason your plant keeps chasing the same sanitation, downtime, and quality issues—over and over again. Biofilms aren’t just buildup or poor

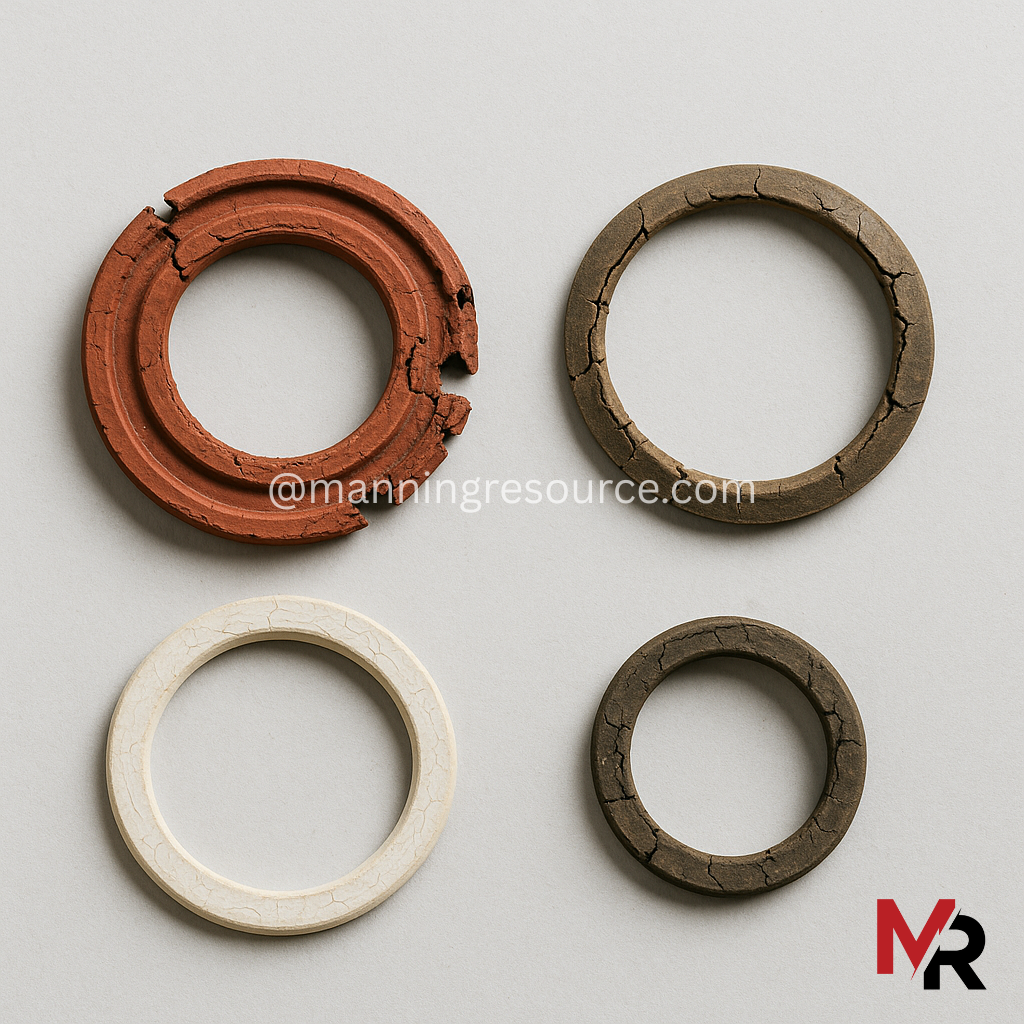

Rubber components – seals, gaskets, diaphragms, and O-rings, might look fine at a glance, but hidden chemical degradation and dry rot could be quietly destroying your plant’s integrity. Why It

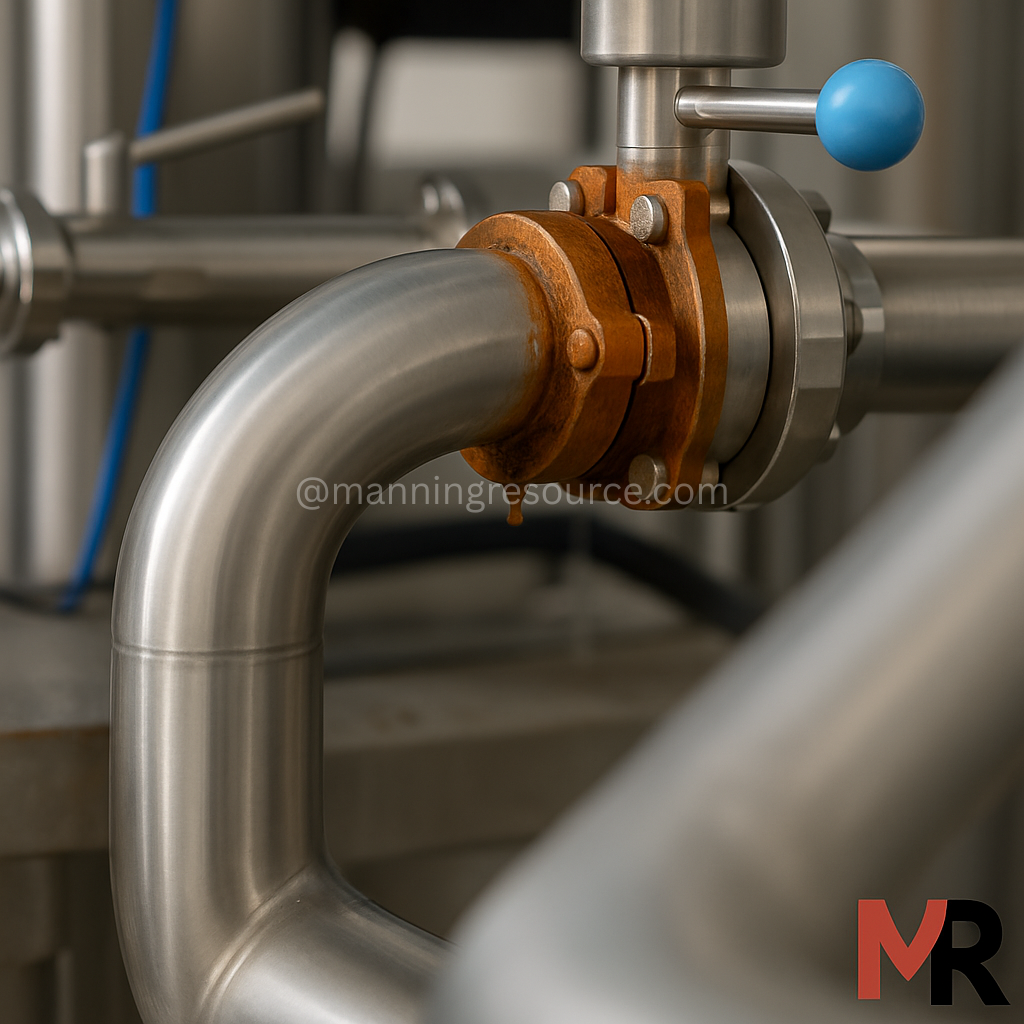

Don’t Let a Small Leak Become a Catastrophic Failure What might seem like a small leak from a pipe joint is a signal that something much more dangerous is brewing.

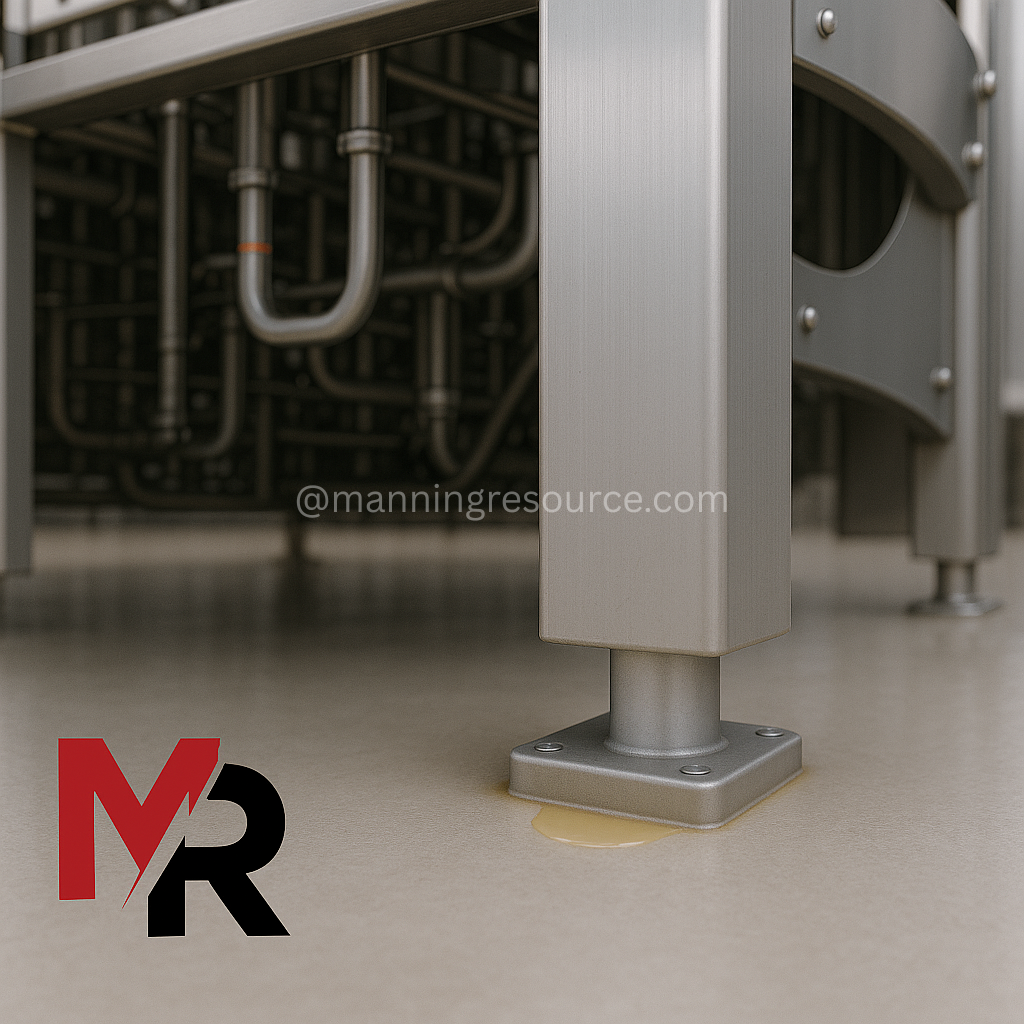

In today’s food and beverage manufacturing environments, sanitation isn’t just about the visible surfaces, it’s about the spaces we don’t see. One of the most overlooked vulnerabilities lies at the

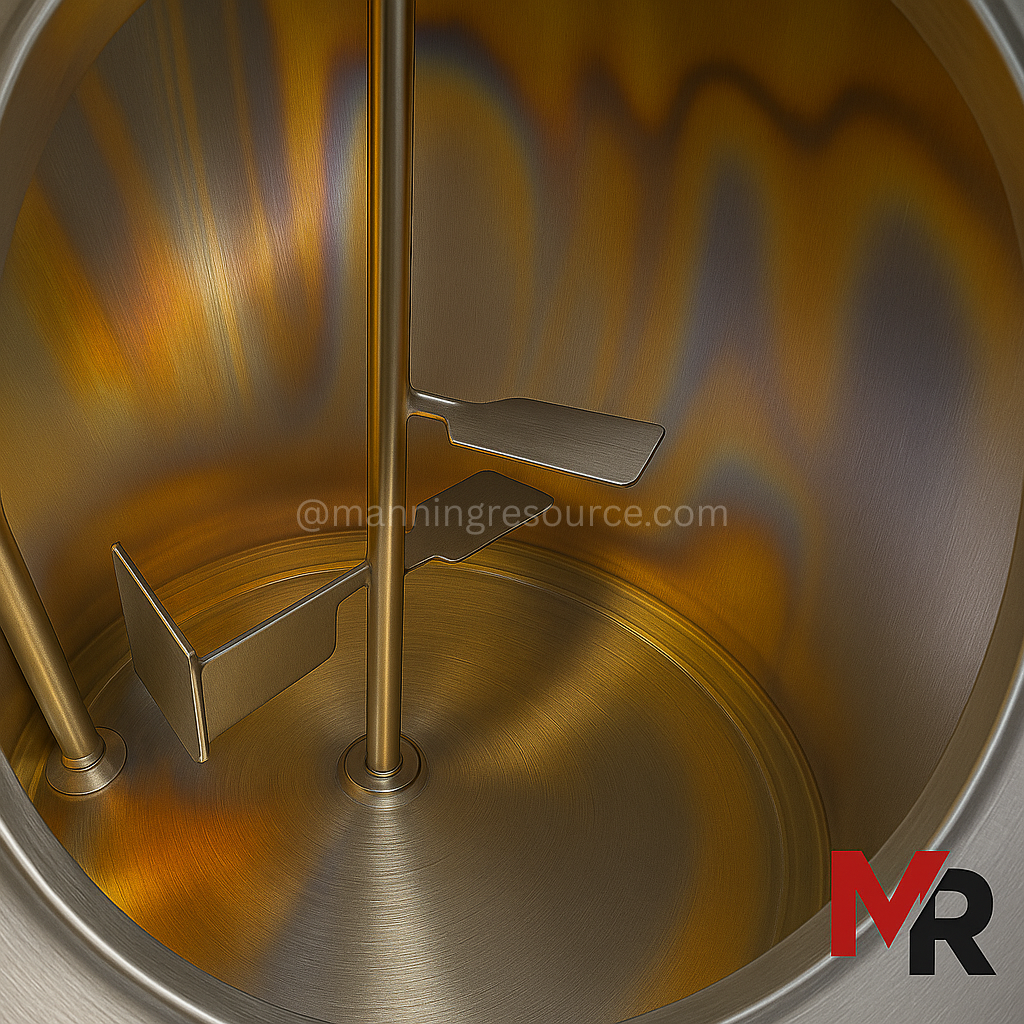

Discoloration on the inside of your stainless-steel tank, whether it’s rouging, rainbow hues, or rust-like stains—should raise an immediate red flag. These marks aren’t just cosmetic; they’re indicators that something

Rework is one of the biggest challenges in manufacturing plants, often lurking in warehouse corners, cluttered and unmanaged. But before diving into reworking defective products, ask yourself: Is it worth

Let’s be honest, everyone loves audit day when the seals on your dock doors look pristine. But what about the rest of the year? Dock and door seals are one

In food manufacturing, it’s often what you don’t see that poses the greatest risk. Behind the smooth walls of your mixers, blenders, and conveyors, bushings and seals are quietly working,