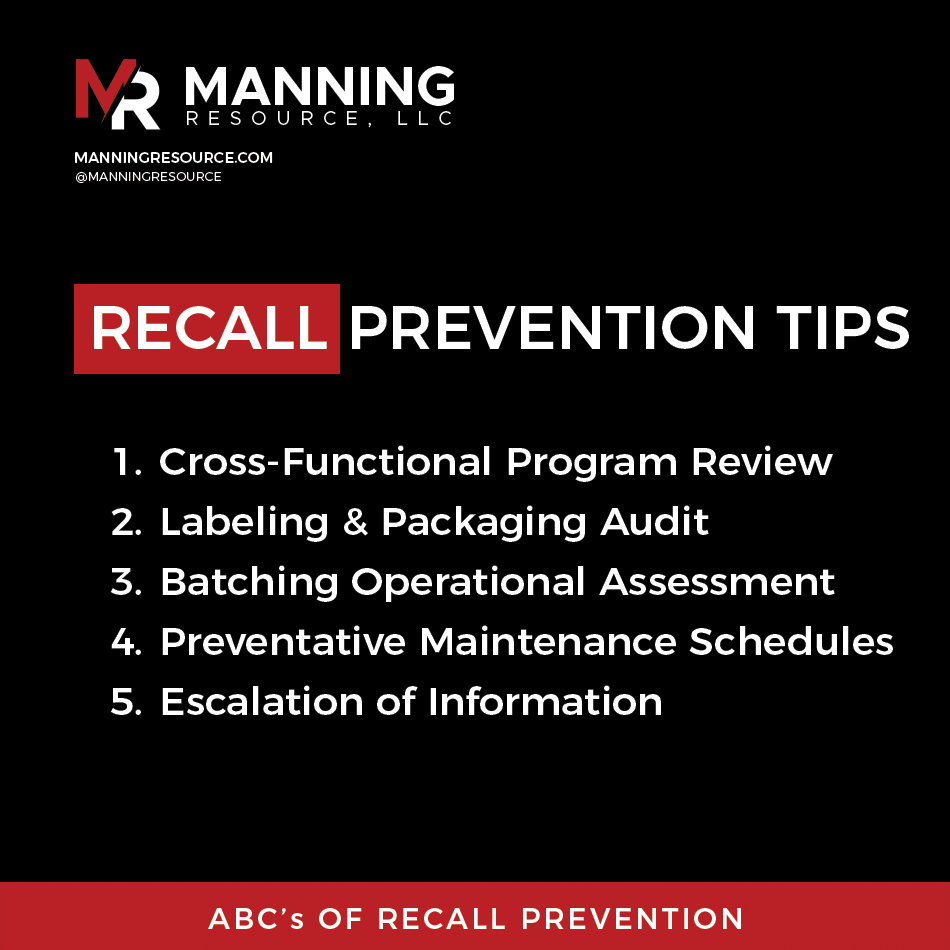

As we dive into 2025, the food and beverage industry continues to face challenges with recalls that can cost millions, damage reputations, and compromise consumer trust. After analyzing recent recall cases during the second week of the year, it’s clear that proactive strategies are key to preventing such incidents. Here are five critical recall prevention tips your organization can implement today:

- Cross-Functional Program Review

Ensure that all departments—from quality assurance to operations, are aligned. Regular program reviews help identify gaps in processes and ensure everyone is working towards the same food safety and quality goals. - Labeling & Packaging Audit

Mislabeling is one of the most common recall triggers. Conduct frequent audits of labeling and packaging processes to verify accuracy, prevent allergen misstatements, and ensure regulatory compliance. - Batching Operational Assessment

Review your batching procedures to ensure proper sequencing and documentation. Small inconsistencies can lead to significant product errors that might otherwise be missed until it’s too late. - Preventative Maintenance Schedules

Equipment failures often result in foreign material contamination risks. Stick to a detailed, consistent preventative maintenance schedule to avoid unexpected breakdowns that could compromise product safety. - Escalation of Information

Foster a culture where employees feel empowered to escalate potential food or human safety concerns immediately. Early detection of issues often prevents them from evolving into costly recalls.

By adopting these actionable steps, you can help mitigate risks and safeguard your organization from the far-reaching consequences of a product recall. Consistent attention to these practices builds a stronger foundation of food safety, quality, and consumer trust.

Add Comment