Conveyor belts are the backbone of food and beverage manufacturing—moving product through each step with speed and precision. But when these belts begin to wear or delaminate, especially along the edges or top surface, they stop being silent helpers and start becoming hidden risks.

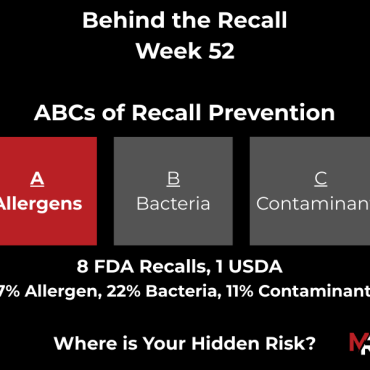

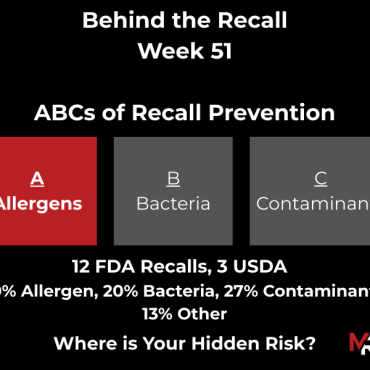

A single crack, frayed edge, or exposed thread can challenge the very foundation of recall prevention—the ABCs: Allergens, Bacteria, and Contaminants (Foreign Materials).

- Allergens – Frayed belts can harbor residue, leading to cross-contact risks.

- Bacteria – Cracks and worn areas create harborage points, even after cleaning.

- Contaminants – Delaminated belt fragments can enter product streams undetected.

These are not minor maintenance issues—they’re missed opportunities in prevention that can escalate into full-blown recalls, regulatory action, and brand damage.

3 Prevention Tips Every Facility Should Apply

- Inspect Daily – Incorporate belts into pre-op and mid-shift inspections, focusing on edges and seams.

- Train Teams – Equip operators to recognize early wear before it leads to product contamination.

- Replace Proactively – Don’t wait for breakdown; follow scheduled replacement intervals to stay ahead.

The Takeaway

Your belts may not always be the first thing you think of in recall prevention—but ignoring them is a missed opportunity that undermines your safeguards. Small signs of wear today can become tomorrow’s headlines.

At Manning Resource, we help companies close these gaps before they become failures. Learn more about how our Recall Prevention Programs can protect your brand and bottom line.

Add Comment